Welding

We offer a full range of welding services; our team are fully trained in Manual Metal Arc (Stick) , Mig and Tig Welding, which enables us to provide the best welding technique suited to your project. We Specialise in Steel, Stainless Steel and Aluminium welding. Below is some information about the different types of welding techniques to help you choose.

MMAW

Manual Metal Arc Welding also known as Stick Welding, uses a consumable electrode (stick) which is coated in flux and when it touches the workpiece forms and arc and lays the weld, it is the most commonly used welding process because of it's simplicity and is mainly used for construction of steel and industrial fabrication. Main advantages are simplicity of equipment and operation.

MIG Welding

Metal Inert Gas (MIG) is the most commonly used industrial process it works by producing an arc between the work piece and the wire electrode which heats the metal and causes it to melt then and join together Along with the wire electrode, a shielding gas feeds through the welding gun, which shields the process from contaminants in the air the main advantage is speed.

TIG Welding

Tungsten Inert Gas (TIG) normally used on thin work pieces is a welding process that uses a tungsten electrode to produce the weld pool then a filler rod is added. The weld pool is protected from atmospheric contamination by an inert shielding gas (argon or helium),

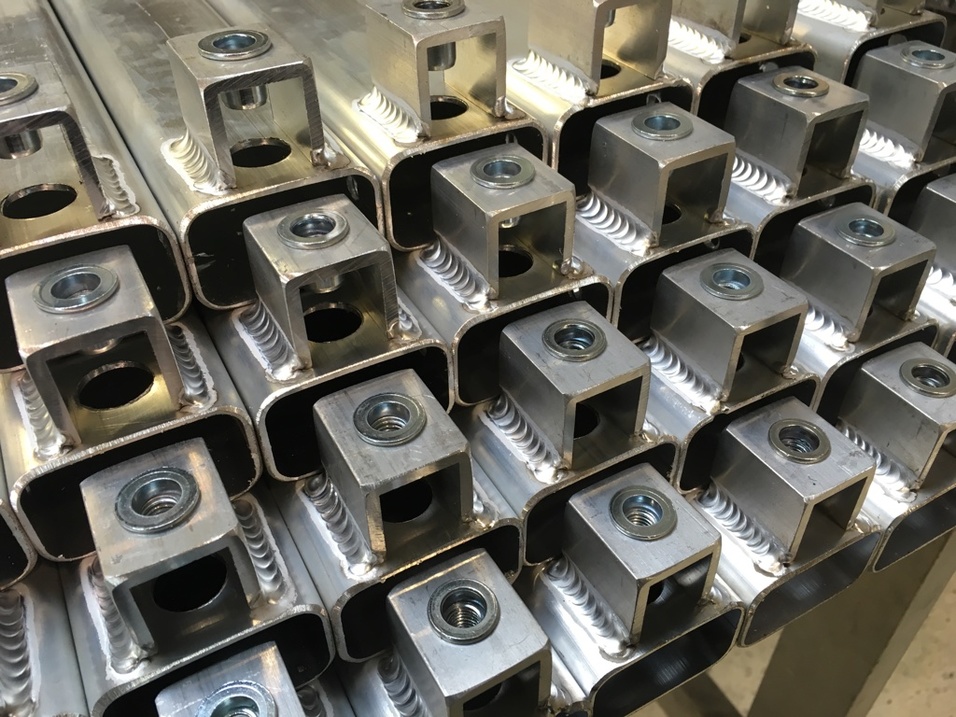

The advantages of TIG Welding is greater control over the weld allowing for a more high quality weld which is also aesthetically pleasing. We are specialist in Aluminium TIG welding.

The advantages of TIG Welding is greater control over the weld allowing for a more high quality weld which is also aesthetically pleasing. We are specialist in Aluminium TIG welding.